The flavour of the week has been “chaos”. Again!

The flavour of the week has been “chaos”. Again!

Chaos dissipates energy faster than calm so chaotic behaviour is a symptom of an inefficient design.

And we would like to improve our design to restore a state of ‘calm efficiency’.

Chaos is a flow phenomenon … but that is not where the improvement by design process starts. There is a step before that … Safety.

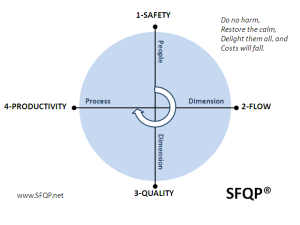

Safety First

If a design is unsafe it generates harm. So we do not want to improve the smooth efficiency of the harm generator … that will only produce more harm! First we must consider if our system is safe enough.

Despite what many claim, our healthcare systems are actually very safe. For sure there are embarrassing exceptions and we can always improve safety further, but we actually have quite a safe design.

It is not a very efficient design though. There is a lot of checking and correcting which uses up time and resources … but it helps to ensure safety is good enough for now.

Having done the safety sanity check we can move on to Flow.

Flow Second

Flow comes before quality because it is impossible to deliver a high quality experience in a chaotic system. First we need to calm any chaos. Or rather we need to diagnose the root causes of the chaotic behaviour and do some flow re-design to restore the calm.

Chaos is funny stuff. It does not behave intuitively. Time is always a factor. The butterflies wing effect is ever present. Small causes can have big effects, both good and bad. Big causes can have no effect. Causes can be synergistic and they can be antagonistic. The whole is not the sum of the parts. This confusing and counter-intuitive behaviour is called “non linear” and we are all rubbish at getting a mental handle on it. Our brains did not evolve that way.

The good news is that when chaos reigns it is usually possible to calm it with a small number of carefully placed, carefully timed, carefully designed, synergistic, design “tweaks”.

The problem is that when we do what intuitively feels “right” we can too easily make poor improvement decisions that lead to ineffective actions. The chaos either does not go away or it gets worse. So, we have learned from our ineptitude to just put up with the chaos and to accept the inefficiency, the high cost-of-chaos.

To calm the chaos we have to learn how to use the tools designed to do that. And they do exist.

Quality

Safety and Flow represent the “absolute” half of the SFQP cycle. Harm is an absolute metric. We can devise absolute definitions and count harmful events. Mortality. Mistakes. Hospital acquired infections. That sort of stuff.

Flow is absolute too in the sense that the Laws of Physics determine what happens, and they are absolute too. And non-negotiable.

Quality is relative. It is the ratio of experience and expectation and both of these are subjective but that is not the point. The point is that it is a ratio and that makes it a relative metric. My expectation influences my perception of quality, as does what I experience. And this has important implications. For example we can reduce disappointment by lowering expectation; or we can reduce disappointment by improving experience. Lowering expectation is the easier option because to do that we only have to don the “black hat” and paint a grisly picture of a worst case scenario. Some call it “informed consent”; I call it “abdication of empathy” and “fear-mongering”.

Variable quality can come from variable experience, variable expectation or both. So, to reduce quality variation we can focus on either input to the ratio; and the easiest is expectation. Setting a realistic expectation just requires measuring experience retrospectively and sharing it prospectively. Not satisfaction mind you – Experience. Satisfaction surveys are largely meaningless as an improvement tool because just setting a lower expectation will improve satisfaction!

And this is why quality follows flow … because if flow is chaotic then expectation becomes a lottery, and quality does too. The chaotic behaviour of the St.Elsewhere’s® A&E Department that we saw last week implies that we cannot set any other expectation than “It might be OK or it might be Not OK … we cannot predict. So fingers crossed.” It is a quality lottery!

But with calm and efficient flow we experience less variation and with that we can set a reasonable expectation. Quality becomes predictable-within-limits.

Productivity

Productivity is also a relative concept. It is the ratio of what we get out of the system divided by what we put in. Revenue divided by expense for example.

And it does not actually emerge last. As soon as safety, flow or quality improve then they will have an immediate impact on productivity. Work gets easier. The cost of harm, chaos and disappointment will fall (and they are surprisingly large costs!).

The reason that productivity-by-design comes last is because we are talking about focussed productivity improvement-by-design. Better value for money. And that requires a specific design focus. And it comes last because we need some head-space and some life-time to learn and do good system design.

And SFQP is a cycle so after doing the Productivity improvement we go back to Safety and ask “How can we make our design even safer and even simpler?” And so on, round and round the SFQP loop.

Do no harm, restore the calm, delight for all, and costs will fall.

And if you would like a full-size copy of the SFQP cycle diagram to use and share just click here.

47 Replies to “SFQP”